Harga Pabrik Gulungan Baja Tahan Karat 304 304L Gulungan Tiis

| barang | nilai |

| Aplikasi | Hiasan, Dapur, jsb. |

| Kandel | 0.3-50mm |

| Standar | GB |

| Lebar | 3mm-2000mm atanapi sakumaha anu diperyogikeun |

| Sertipikat | API, ce, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 |

| Kelas | Seri 300 |

| Toleransi | ±1% |

| Layanan Pangolahan | Ngelas, Nyetrika, Motong, Ngalengkung, Nyetrika |

| Kelas Baja | 301L, S30815, 301, 304N, 310S, S32305, 410, 204C3, 316Ti, 316L, 441, 316, 420J1, L4, 321, 410S, 436L, 410L, 443, LH, L1, S32304, 314, 347, 430, 309S, 304, 439, 425M, 409L, 420J2, 204C2, 436, 445, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L |

| Beungeut Rengse | TSHS |

| Waktos pangiriman | 8-14 dinten |

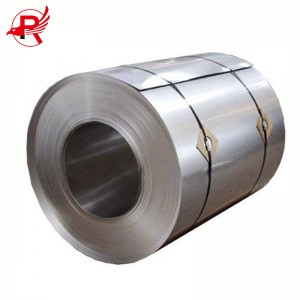

| Ngaran produk | Kumparan Baja Tahan Karat |

| Téhnik | Digulung Tiis Digulung Panas |

| Tipe | Strip Kumparan Pelat Lambaran |

| Standar | AISI ASTM JIS DIN GB |

| Beungeut | BA / 2B / NO.1 / NO.3 / NO.4 / 8K / HL / 2D / 1D |

| Panjangna | Pamundut Konsumén |

| MOQ (Modal Usaha) | 1 Ton |

| Aplikasi | Konstruksi |

| Bungkusan | Bungkusan Standar anu Layak Di Laut |

| Pamayaran | Deposit 30% + Uang Muka 70% |

Baja tahan karat 304 304L anu nawiskeun kamampuan las anu saé, tahan korosi anu saé sareng kakuatan anu luhur. Ieu mangrupikeun bahan anu idéal pikeun rupa-rupa aplikasi kalebet alat pangolahan dahareun sareng alat pangolahan kimia.

Di handap ieu daptar sababaraha aplikasi anu langkung umum pikeun gulungan baja tahan karat 304 304L:

1. Alat Pangolahan Kadaharan & Alat Pangolahan Kimia

2. Industri Minyak & Gas

3. Aplikasi Kelautan

Catetan:

1. Sampling gratis, jaminan kualitas saatos penjualan 100%, Ngarojong metode pamayaran naon waé;

2. Sadaya spésifikasi pipa baja karbon buleud anu sanés sayogi numutkeun kabutuhan anjeun (OEM & ODM)! Harga pabrik anu anjeun bakal kéngingkeun ti ROYAL GROUP.

Komposisi Kimia Kumparan Baja Tahan Karat

| Komposisi Kimia % | ||||||||

| Kelas | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0 .15 | ≤0 .75 | 5. 5-7. 5 | ≤0.06 | ≤ 0.03 | 3.5 -5.5 | 16 .0 -18.0 | - |

| 202 | ≤0 .15 | ≤l.0 | 7.5-10.0 | ≤0.06 | ≤ 0.03 | 4.0-6.0 | 17.0-19.0 | - |

| 301 | ≤0 .15 | ≤l.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 302 | ≤0 .15 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 8.0-10.0 | 17.0-19.0 | - |

| 304 | ≤0 .0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-10.5 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.035 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0 .03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0 - 15.0 | 16 .0 -1 8.0 | 2.0 -3.0 |

| 321 | ≤ 0 .08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0 - 13.0 | 17.0 -1 9.0 | - |

| 630 | ≤ 0 .07 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | 3.0-5.0 | 15.5-17.5 | - |

| 631 | ≤0.09 | ≤1.0 | ≤1.0 | ≤0.030 | ≤0.035 | 6.50-7.75 | 16.0-18.0 | - |

| 904L | ≤ 2 .0 | ≤0.045 | ≤1.0 | ≤0.035 | - | 23.0·28.0 | 19.0-23.0 | 4.0-5.0 |

| 2205 | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.02 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 |

| 2507 | ≤0.03 | ≤0.8 | ≤1.2 | ≤0.035 | ≤0.02 | 6.0-8.0 | 24.0-26.0 | 3.0-5.0 |

| 2520 | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤ 0.03 | 0.19 -0.22 | 0. 24 -0. 26 | - |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 430 | ≤0.1 2 | ≤0.75 | ≤1.0 | ≤ 0.040 | ≤ 0.03 | ≤0.60 | 16.0 -18.0 | |

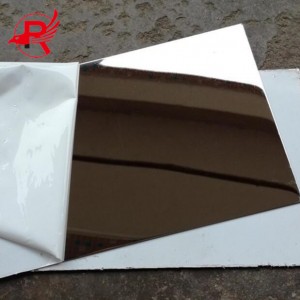

Ngaliwatan sababaraha metode pamrosésan anu béda-béda tina rolling tiis sareng pamrosésan ulang permukaan saatos rolling, lapisan permukaan gulungan stainless steel 304 304L tiasa gaduh jinis anu béda-béda.

Pangolahan permukaan gulungan stainless steel ngagaduhan NO.1, 2B, No. 4, HL, No. 6, No. 8, BA, TR hard, Rerolled bright 2H, polishing bright sareng lapisan permukaan sanésna, jsb.

1. Lapisan No.1: Lapisan ieu didamel tina baja tahan karat anu digulung panas kalayan karasana sareng kusam anu khusus. Ieu mangrupikeun lapisan anu paling umum dianggo sareng gaduh penampilan anu langkung kasar.

2. 2B Finish: Ieu mangrupikeun finish reflektif anu lemes anu kahontal ku baja tahan karat anu digulung tiis. Finishing 2B nyaéta finishing permukaan baja tahan karat anu paling seueur dianggo.

3. BA Finish: Lapisan akhir ieu mibanda penampilan anu mantul pisan, siga eunteung. Ieu kahontal ku cara ngagosok stainless steel ku bahan abrasif anu beuki lemes dugi ka permukaan anu dipoles kalayan sampurna.

4. Lapisan No.4: Lapisan ieu katingalina disikat atanapi sapertos satin, kahontal ku cara nyiptakeun pola disikat searah dina permukaan baja tahan karat.

5. Poles No.8: Ieu mangrupikeun hasil akhir anu paling mantul sareng siga eunteung, anu kahontal ku cara ngagosok stainless steel nganggo abrasif anu lemes pisan dugi ka permukaanana mantul pisan.

Prosés produksi gulungan stainless steel biasana ngalibatkeun sababaraha tahapan, diantarana:

1. Peleburan: Prosés produksi dimimitian ku peleburan bahan baku sapertos beusi, nikel, kromium, jsb. dina tungku.

2. Ngabentuk: Tuangkeun baja cair kana citakan pasagi panjang atanapi ingot baja, teras gulung kana pelat datar atanapi gulungan.

3. Annealing: Lambaran atawa koil baja tahan karat tuluy dianneal, atawa dipanaskeun jeung didinginkan dina lingkungan anu dikontrol, pikeun ngurangan setrés sarta ningkatkeun kakuatan jeung daktilitas logam.

4. Ngagulung tiis: Baja tahan karat teras digulung tiis, atanapi dilebetkeun kana runtuyan gulungan, pikeun ngirangan ketebalanna sareng ningkatkeun hasil akhir permukaanana.

5. Anil sareng pengawetan: baja tahan karat teras dianil sareng diasinkeun, atanapi dirawat ku larutan asam pikeun miceun kokotor permukaan sareng ningkatkeun daya tahan korosi.

6. Panyelesaian: Gulungan baja tahan karat teras dipotong dumasar ukuran sareng dibéré perlakuan permukaan anu béda-béda sapertos ngagosok, ngagiling atanapi ngalapis.

7. Kontrol Kualitas: Sapanjang prosés produksi, gulungan baja tahan karat dipariksa sareng diuji pikeun mastikeun yén éta nyumponan sarat kakuatan, résistansi korosi sareng permukaan anu sampurna.

bungkusan laut standar tina 304 304L coil stainless steel

Bungkusan laut ékspor standar:

Gulungan Kertas Tahan Cai + Pilem PVC + Pita Pangiket + Palet Kai atanapi Wadah Kai;

Bungkusan khusus sakumaha pamundut anjeun (Logo atanapi eusi sanés anu ditampi dicitak dina bungkusan);

Bungkusan khusus anu sanésna bakal dirancang salaku pamundut palanggan;

Transportasi:Pangiriman Ekspres (Pangiriman Sampel), Udara, Rel, Darat, Laut (FCL atanapi LCL atanapi Curah)

Q: Naha produsén ua?

A: Muhun, kami produsén. Kami gaduh pabrik nyalira anu aya di Kota Tianjin, Cina. Salian ti éta, kami damel bareng sareng seueur perusahaan milik nagara, sapertos BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, jsb.

Q: Dupi abdi tiasa mesen sababaraha ton kanggo uji coba?

A: Tangtosna. Kami tiasa ngirimkeun kargo kanggo anjeun nganggo layanan LCL. (Muatan kontainer kirang)

Q: Upami sampel gratis?

A: Sampel gratis, tapi anu mésér mayar ongkos kirimna.

Q: Naha anjeun supplier emas sareng ngalakukeun jaminan perdagangan?

A: Kami supplier emas tujuh taun sareng nampi jaminan perdagangan.